Engineering – Dissertation

The durability of concrete is greatly reduced by the presence of micro-cracks that develop within the material. Micro-cracks may develop due to various processes and can occur at any time of curing or during the service life of the material. Micro-cracks have a negative effect on the concrete as they allow ingress of liquids or gases into the concrete matrix contributing to further deterioration. Therefore, the crack must be controlled and ideally healed in as short a time as possible.

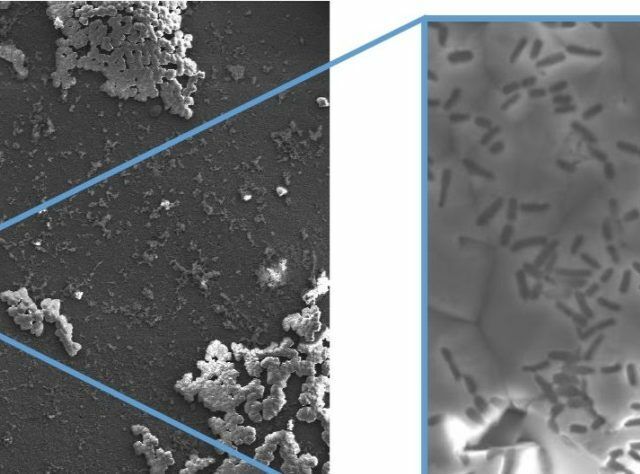

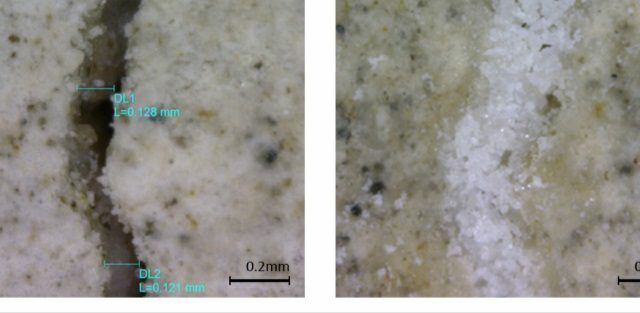

Under certain conditions, these micro-cracks can heal naturally through autogenous healing. This involves the precipitation of calcium carbonate inside the crack in the presence of water. However, autogenous healing is only possible in small cracks and takes a long time to occur. Cracks may also heal through a natural microbial process involving deposition of calcium carbonate. This biological repair technique that utilises bacteria can be artificially induced, indeed it occurs naturally in the presence of certain nutrients that include a nitrogen source essential for bacterial growth and replication. The calcium carbonate (CaCO3) deposition by bacteria allows filling of cracks in concrete and plugging of pores to reduce absorption. As opposed to autogenous healing, this process occurs rapidly and can therefore seal cracks a lot quicker and avoid further damage occurring. Bio-deposition methods as opposed to conventional surface treatments and crack healing methods are alternative and eco-friendly techniques which are currently being investigated at the University of Malta. The microbial process is borrowed from nature and produces no pollution, and has no damaging effects on the natural environment. Therefore, it serves as an alternative method to conventional treatments on concrete in an effort to counteract the adverse impacts of these methods on our natural environment.The new technique provides a viable and inexpensive alternative. Different methods exist for the application of bacteria to heal micro-cracks which vary from surface treatment to encapsulation. The choice of bacteria is also crucial since these must be adapted to the prevailing environmental conditions to which the concrete is exposed.

The aim of the research was to assess the potential of using different bacterial strains for the self-healing of cracks in concrete and to study the effects of this treatment on the absorption properties of the concrete. The specific objectives of this study were to cultivate different bacterial strains and determine the types and concentration of nutrients needed to induce optimum growth, to characterise the carbonate precipitates obtained through the microbial process. Carbonate deposition on pre-cracked concrete samples was also measured combined with testing the crack healing capacity of this process.

Through these studies, it was confirmed that microbial deposition of calcium carbonate could be induced successfully on concrete. Furthermore, the characterisation of the precipitates confirmed that the crystals precipitated on these samples were Calcium carbonate (CaCO3)crystals.It was also noted that samples exposed to more than one round of microbial treatment exhibited a greater and more even coating of carbonate crystals on the surface. This proves that repeated cycles of treatment are effective in increasing the amount of CaCO3 deposition and therefore, increasing its crack healing capacity.

The jury awarded the First Prize in this Category to Christine, stating that “apart from investigating a very innovative subject which could have a practical use, the author had gone through all the stages of a well-researched study, by indicating a good grasp of the subject under study and the material properties, and by carrying out an exhaustive number of tests to confirm the validity of the proposed solution, the characterisation of the resulting precipitate, and the influence of the proposed treatment on the crack healing and absorption characteristics of mortar samples. The thoroughness of the research, the clarity of the logical sequence of laboratory tests carried out, and the explanation, in relatively simple terms, of the chemical processes involved, were also related very well during the presentation.“

Acknowledgement: ERDF (Malta) for the financing of the testing equipment through the project: ‘‘Developing an Interdisciplinary Material Testing and Rapid Prototyping R&D Facility (Ref. no. 012)’’.

Date:

July 19, 2024